Elektrodi SPEZIAL 2.0mm*350mm

Item No.

4211040-20.1

Properties and Applications SPEZIAL is a basic, double-coated multi-purpose MMA electrode. The composition of the double coating confers exceptionally good welding characteristics and a highly stable and directional arc. Very good gap bridging and ideally suited for root passes and positional

Description

| Properties and Applications |

SPEZIAL is a basic, double-coated multi-purpose MMA electrode. The composition of the double coating confers exceptionally good welding characteristics and a highly stable and directional arc. Very good gap bridging and ideally suited for root passes and positional welding. The glassy slag is easily removed from the finely-rippled weld seams, the excellent welding characteristics and ISO-V toughness to -30°C. |

|

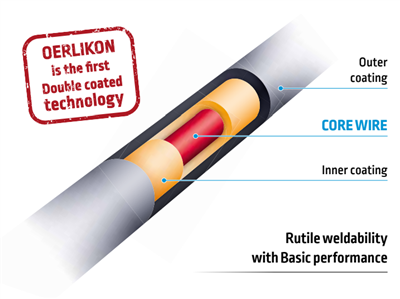

| What is double coating |

A double-coated electrode consists of two separate layers: The “outer layer” with higher basicity The “inner layer” rutil-acid The arc-stabilizing minerals and metal powders are concentrated in the inner coating, and the minerals delivering the gas shielding are concentrated in the outer coating. This combination enables unique weldability characteristics. During manufacturing the two coatings are pressed simultaneously in a single extrusion operation. Both coatings from different chemical compositions but very complementary, will give a better technical result |

|

| Features |

|

| CUSTOMER BENEFITS |

|

| Standards | |

AWS/ASME SFA - 5.1 | E 7016-H8 |

EN ISO 2560 - A | E 38 3 B 12 H10 |

| Typical Chemical Values of Weld Metal | |||||||

| Type of Analysis | C | Si | Mn | S | P | ||

| Weld Deposit | 0.06 | 0.7 | 0.9 | ≤0.015 | ≤0.020 | ||

| Typical Mechanical Values of Weld Metal (%) | |||||

| Test Condition | Yield Strength (N/mm²) | Tensile Strength (N/mm²) | Elongation A5 (%) | Charpy V-Notch Properties (J) | |

| As welded | ≥ 380 | 470-600 | ≥ 25 | +20 °C → ≥ 150 | -30°C → ≥ 60 |

| Application Information | |

| Welding Positions : |       |

| Polarity: |

|

| Deposition Data | ||||||

| Current | Time | Deposition Rate @ 90 Imax | Diameter x Length | Deposition efficiency (%) | Number of electrodes/ kg weld metal | Voltage |

| 55-65(A) | -(sec.) | - (kg/h) | 2.0 x 350 (mm) | - (%) | - | - (V) |

| Approvals |

ABS 3Y H5 BV 3Y H5 CE EN 13479 DB 10.039.12 DNV-GL 3 YH5 LR 3Y H5 NAKS/HAKC *2.5 - 5.0 mm PRS 3Y H5 RINA 3Y H5 RS 3Y H5 VdTÜV 00690 |

| Approvals are based on factory location. |

| Consumer characteristics | |

Alloy type | Carbon manganese |

Coating type | Basic covering |

Diffusible hydrogen | < 10.0 ml/100g |

Welding current | DC + , AC |

Application | Structural steelwork, production and assembly jobs in industry and for pipeline construction for decades. Material to be welded S(P)235; S(P)355; GP 240; GP 280; L 245; L260. |

Storage & Re-Drying Information |

| Required redry for 2 hour at 250°C - 300°C. Max 5 times. |

Specifications

| Net Weight, kg | 4.2 |

| Gross Weight, kg | 4.3 |

| Gas volume, m 3 | 0 |

| Standard rental price, EUR/day (exl. VAT) | 0 |

Reviews (0)

There are no reviews yet.

Latviešu (Latvija)

Latviešu (Latvija)

Русский (Россия)

Русский (Россия)