argon gas hose 5.0x3.5mm DRY FLOW ISO 3821

Item No.

42349-44

Properties of hose The DRY FLOW hose black is designed for transporting argon, CO2 gases. It corresponds to the latest standard of DIN EN ISO 3821 and thus offers the highest level of occupational safety. It is extremely robust , flexible and resistant to aging and weathering and has

Description

| Properties of hose |

| The DRY FLOW hose black is designed for transporting argon, CO2 gases. It corresponds to the latest standard of DIN EN ISO 3821 and thus offers the highest level of occupational safety. It is extremely robust, flexible and resistant to aging and weathering and has a smooth, dirt-resistant surface structure. The excellent quality has made the hose a valued product for decades in industry, in installation and heating companies, foundries, shipyards, in bridge, steel, bodywork, structural and civil engineering, as well as in welding workshops and for welding equipment manufacturers.- Black, non-porous, smooth EPDM inner layer- Reinforcement: synthetic yarns- Black, smooth EPDM outer layer, ozone. What is the EPDM? Rubber crumb (EPDM) is a high quality primary product, which uses natural or isoprene rubber. The filler is ethylene-propylene components (50...70% of molar mass), which create cyclic chains with rubber (20...40% of molar mass). In the process of polymerization, pigments are added, the output is a homogeneously dyed mass, as a result of which the resulting crumb has a uniform color throughout the structure. As a result, the top layer of the pads is more often laid out precisely from rubber crumb, since its color remains unchanged. |

|

| Summary

of all tests (hoses) | |||||||

Hose material | Permeation | Storage capacity | Drying time | Aging | Classification | ||

Oxygen | Moisture | Moisture | Oxygen | Moisture | |||

| PA | 2 | 5 | 4 | 2 | 6 | 5 | 4.35 |

| PTFE | 3 | 1 | 2 | 3 | 1 | 3 | 1.95 (best, but very hard) |

| PU | 3 | 6 | 6 | 3 | 6 | 2 | 4.65 |

| PVC | 2 | 3 | 4 | 2 | 5 | 2 | 3.25 |

| EPDM | 3 | 3 | 1 | 3 | 2 | 2 | 2.3 (good, more flexible ) |

Typical Applications | |

PUR = | poly urethane |

PTFE = | poly tetra flour ethylene |

PE = | poly ethylene |

EPDM = | Ethylene Propylene Dien Monomer |

assembly hose = | combination of PTFE and something else |

PTFE compound = | PTFE and something else |

compressed air PVC = | Poly vinyl chloride |

| Pores or cracks? – Moisture in the shielding gas |

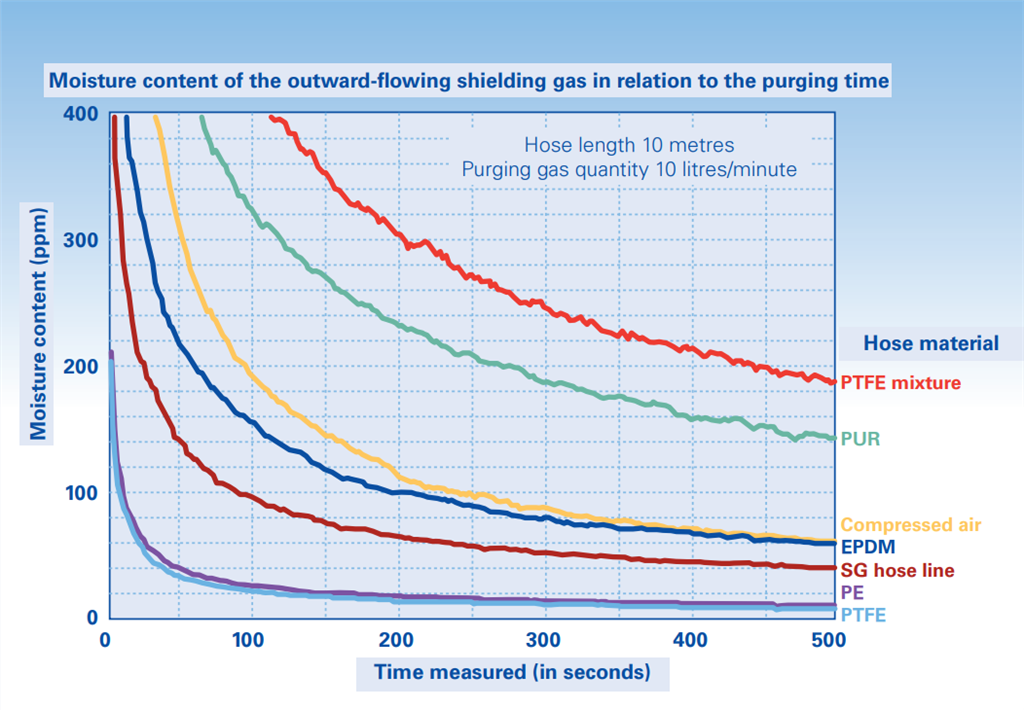

| The purity of a shielding gas plays an important role both in processing sensitive metals such as titanium and in welding common structural steels and aluminium. The quality requirements for shielding gases for welding are defined in the ISO 14175 standard. In spite of the high level of gas purity, pores or hydrogen cracks are a frequent occurrence. The most common cause for this is moisture. This is introduced mainly through the gas hoses, as well as through leaks in the gas supply system. The shielding gases should be supplied using hoses that comply with ISO 3821 (formerly 559). These hoses can be easily recognized since the name of the standard is imprinted on them. Many users use compressed-air hoses of the quality typically available in DIY superstores. While they cost significantly less, they do have clear disadvantages: the moisture in the air passes through the wall of the hose to the inside, where it is transferred to the dry shielding gas and only slowly purged again |

Specifications

| Manufacturer code: | 002349/44/050 |

| Net Weight, kg | 0.1 |

| Gross Weight, kg | 0.11 |

| Gas volume, m 3 | 0 |

| Standard rental price, EUR/day (exl. VAT) | 0 |

Reviews (0)

There are no reviews yet.

Latviešu (Latvija)

Latviešu (Latvija)

Русский (Россия)

Русский (Россия)