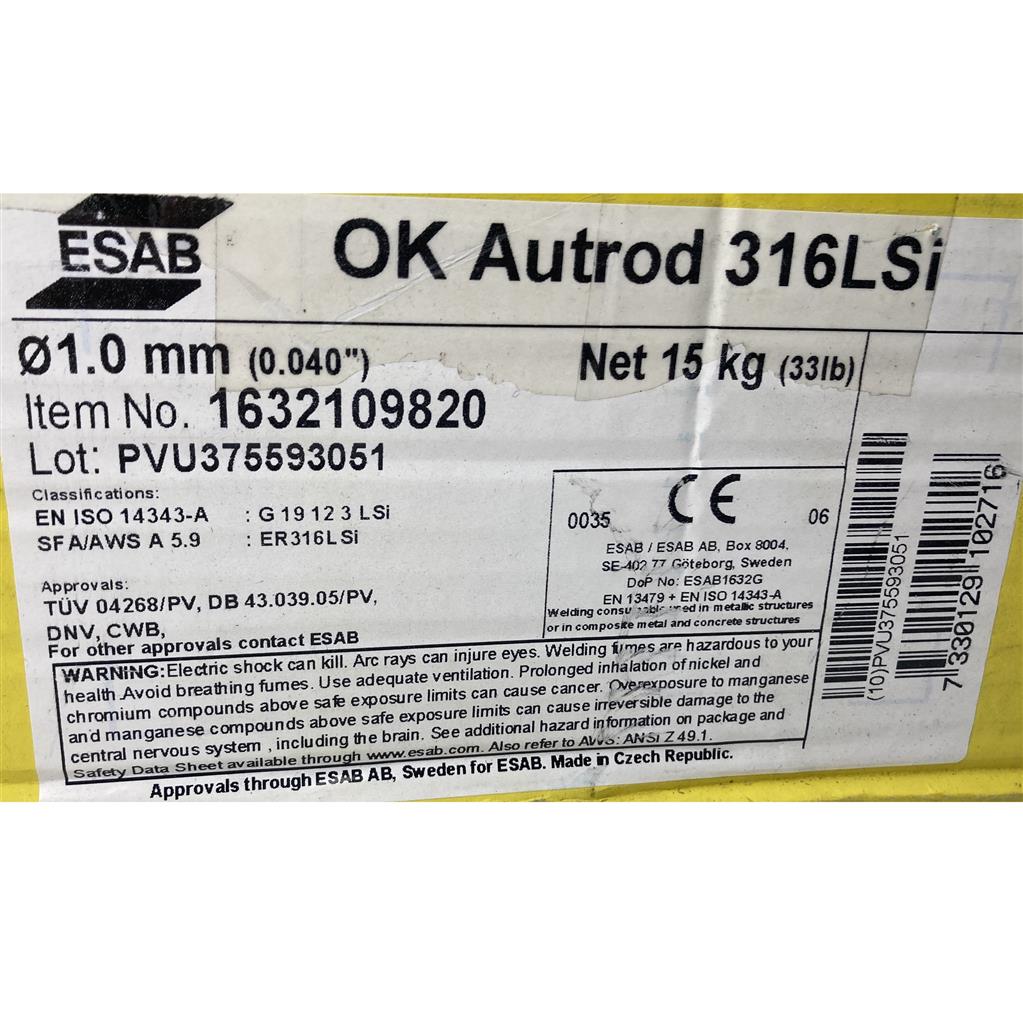

Stieple OK AUTROD 316 LSI 1.0mm/15kg

Item No.

4210077

A continuous, solid, corrosion-resistant, chromium-nickel-molybdenum wire for welding austenitic stainless alloys of the 18% Cr -8% Ni and 18% Cr -10% Ni -3% Mo types. OK Autrod 316LSi has good general corrosion resistance; in particular, the alloy has very good resistance to corrosion in acid and

Description

A continuous, solid, corrosion-resistant, chromium-nickel-molybdenum wire for welding austenitic stainless alloys of the 18% Cr -8% Ni and 18% Cr -10% Ni -3% Mo types. OK Autrod 316LSi has good general corrosion resistance; in particular, the alloy has very good resistance to corrosion in acid and chlorinated environments. The alloy has a low carbon content which makes it particularly recommended when there is a risk of intergranular corrosion. The higher silicon content improves the welding properties such as wetting. The alloy is widely used in the chemical and food processing industries, as well as in shipbuilding and various types of architectural structure.

Typical Charpy V-Notch Properties

| Impact Value | Testing Temperature | |||

| As Welded | ||||

| 70 J (52 ft-lb) | -110 degC (-166 degF) | |||

| 45 J (33 ft-lb) | -196 degC (-321 degF) | |||

| 95 J (70 ft-lb) | -60 degC (-76 degF) | |||

| 120 J (89 ft-lb) | 20 degC (68 degF) | |||

Typical Tensile Properties

| Condition | As Welded | As Welded |

| Shielding Gas | Tested at 350°C. | |

| Tensile Strength | 560 MPa (81 ksi) | 440 MPa (64 ksi) |

| Yield Strength | 400 MPa (58 ksi) | 340 MPa (49 ksi) |

| Elongation | 37 % | 26 % |

Recommended Welding Parameters

| Wire Diameter | ||||

| 0.6 mm (0.025 in.) | ||||

| 1.14 mm (0.045 in.) | ||||

Deposition Data

| Current | Deposition Rate | Diameter | Voltage | Wire Feed Speed |

| 65-220 A | 1.1-5.4 kg/h (2-11 lb/h) | 0.9 mm (0.035 in.) | 15-28 V | 3.5-18.0 m/min (138-709 in./min) |

| 80-240 A | 1.5-6.0 kg/h (3-13 lb/h) | 1.0 mm (0.040 in.) | 15-28 V | 4.0-16.0 m/min (157-630 in./min) |

| 100-300 A | 1.6-7.5 kg/h (3-16 lb/h) | 1.2 mm (0.047 in.) | 15-29 V | 3.0-14.0 m/min (118-551 in./min) |

| 230-375 A | 5.2-8.6 kg/h (11-19 lb/h) | 1.6 mm (1/16 in.) | 23-31 V | 5.5-9.0 m/min (217-354 in./min) |

| 55-160 A | 1.0-4.1 kg/h (2-9 lb/h) | 0.8 mm (0.030 in.) | 12-24 V | 4.0-17.0 m/min (157-669 in./min) |

Classifications

| Wire Electrode | SFA/AWS A5.9 : ER316LSi Werkstoffnummer : ~1.4430 EN ISO 14343-A : G 19 12 3 L Si |

Approvals

| Approvals | CE EN 13479 CWB ER316LSi DB 43.039.05 DNV-GL VL 316 L (M13) NAKS/HAKC 0.8-1.2 mm VdTÜV 04268 |

| Approvals are based on factory location. Please contact ESAB for more information. |

Consumable Characteristics

| Alloy Type | Austenitic (with approx. 8 % ferrite) 19% Cr - 12% Ni - 3% Mo - Low C - High Si |

Typical Weld Metal Analysis %

| Typical Wire Composition % | ||||||||||||||

| C | Cr | Cu | Mn | Mo | Ni | P | S | Si | Si+Fe | |||||

| 0.01 % | 18.4 % | 0.12 % | 1.8 % | 2.60 % | 12.2 % | - | - | 0.9 % | 7 % | |||||

| Typical Weld Metal Analysis % | ||||||||||||||

| 0.02 % | 18.5 % | 0.1 % | 1.8 % | 2.7 % | 12 % | 0.015 % | 0.015 % | 0.8 % | - | |||||

Specifications

| Net Weight, kg | 1 |

| Gross Weight, kg | 1 |

| Gas volume, m 3 | 0 |

| Standard rental price, EUR/day (exl. VAT) | 0 |

Reviews (0)

There are no reviews yet.

Latviešu (Latvija)

Latviešu (Latvija)

Русский (Россия)

Русский (Россия)